ActivArmor™ With Diana Hall, Dr. Kevin Kaplan And Eric Miller

The industry leader for custom-made 3D-printed casts and splints in the United States, ActivArmor™ empowers patients with the freedom to be able to maintain their active lifestyles. Now, they begin producing custom-fit, low-cost reusable face masks that achieve a 98.9% to 99.9% bacterial filtration efficiency (BFE) test score. On today’s show, Bob Roark chats with Diana Hall, the President and Founder of ActivArmor™, orthopedic surgeon Dr. Kevin Kaplan, and critical care flight nurse and paramedic Eric Miller about the face masks. Dr. Kaplan and Eric share their experiences wearing the face mask, while Diana explains how they’ve added the product line using their existing technology. They also dive into the company’s cast and its benefits for athletes and regular patients.

—

Watch the episode here:

ActivArmor™ With Diana Hall, Dr. Kevin Kaplan And Eric Miller

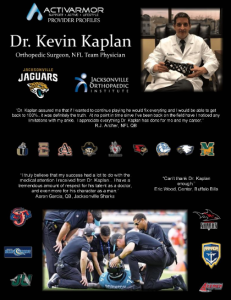

We have three guests on the show. We have Diana Hall. She’s the President and COO of ActivArmor. We have Dr. Kevin Kaplan. He is an orthopedic surgeon with the Jacksonville Orthopedic Institute and Head Team Physician for the Jacksonville Jaguars. We have Eric Miller. He’s a critical care flight nurse and paramedic and a Major in the Wyoming Air National Guard. We’re going to be talking about ActivArmor, both their casts and their face masks. Eric, tell me a little bit about the face masks and why they’re useful and attractive for you to use in your business.

I work on the helicopter, and also work in an ICU. One of the big complaints, if you talk to any healthcare worker about masks, and if you have to wear these things, every time you breathe or exhale, your glasses are fogging up. The ActivArmor mask, I got a 3D scan of my face. This thing fits directly on my face and I don’t get that fog in my glasses. I can tell you, if you’re in a helicopter, you can’t have that happening. It’s a safety issue. Being in an ICU, after twelve-hour shifts, it’s irritating. The other great thing is the ability to be able to see facial expressions and stuff, especially with patients. It’s already scary enough. In this, you can see if you’re smiling. If they have trouble hearing, they can see your lips. They’re a fantastic tool and the fact that they’re N95s, which is great for the situation with the COVID. I use mine all the time.

Eric, you said that you were out flying and that you got your sound boom to work with the mask on.

That’s another big issue for me. I can put my visor down. It works like it goes over my nose and then putting the microphone to the side, I was able to still communicate within the cabin with the other crew members and discuss the patient. It was fantastic.

You were talking about an interest in the hearing-impaired school and potential uses of those masks for the instructors at the school. Could you talk a little bit about your thoughts there?

You were talking about an interest in the hearing-impaired school and potential uses of those masks for the instructors at the school. Could you talk a little bit about your thoughts there?

I was approached by somebody when I was wearing the mask and he says, “I am a teacher for the hearing impaired. Where did you get that mask?” I told them about ActivArmor and he said, “Do you think we can get some of those masks?” I said, “The custom ones, you want to be using them all the time. There’s a price point on those, but they also make some other ones that are probably more affordable for what you’re looking for staff.” As soon as there are materials ready again, I’m going to buy some and have them try it out and see if that works. Being able to see and read the lips is an important aspect of the hearing-impaired community, not just the sign language.

This is a little bit backward, but we got everybody together, which you guys can imagine might be a tad challenging with everybody’s efforts in the community. Diana, if you would, going backward, the mask came along later in the product cycle for you guys. Can you tell me a little bit about how the demand for the product was either requested or developed?

Our regulatory expert at the Robert Fischell Medical Device Institute called knowing that we are the experts in 3D body imaging and custom-fitted exoskeletons, meaning that we do 3D body imaging and we do custom designs for medical devices that fit your body map perfectly. The real issue that they were having with the FDA face mask was fitting because the filtration is only as good as the seal. Air is going to take the path of least resistance and try to go around the mask and avoid the filters if it can. In a traditional face mask, whether they’re N95 or any that has filtration rate, the air that circumvents the filters is going to have potentially those viral particulates in it and then get in.

The point of it was the fitting. They called me saying, “We know that you guys do exoskeletons and that fitting is your thing. We wanted to see if you could figure out a way that we could make custom-fitted masks that would fit perfectly,” because everybody’s face is shaped differently. We have different sizes and different cheeks. When I started doing an analysis of the facial features, there are many different dimensions as far as how far out your chin, nose and cheeks stick, how far out they come vertically and horizontally in all three dimensions. It takes a 3D body image scan to get that perfect fit. That’s what Eric was talking about with his mask. Dr. Kaplan also wears one. Everybody’s features are different. When you do start doing that facial analysis, you see how important the custom fit is to your face. You can’t get something off the shelf and expect it to fit perfectly to your face. That’s why they called us and asked me to design something that would be able to seal perfectly those particulates out.

Shifting gears a little bit, Dr. Kaplan, you’re a user of the mask as well in your practice. What’s been your experience as far as ease of use, changing filters and how your patients react to seeing you in the mask?

Shifting gears a little bit, Dr. Kaplan, you’re a user of the mask as well in your practice. What’s been your experience as far as ease of use, changing filters and how your patients react to seeing you in the mask?

The number one thing is protection, protecting ourselves and our patients. In using or seeing other types of masks and people wear other types of masks, a lot of times you’ll see people do the exact thing that you shouldn’t be doing when you’re wearing a mask and trying to prevent yourself from touching your face. People will adjust their masks or pull the mask down. Their hands are all over their face. The one thing that’s appealed to me from the ActivArmor mask is the custom fit and the customer feel. It’s designed specifically to my face. Even the ones that are moldable, it fits your face well. There are a few times that I’ll have to adjust the mask on my face. Patients enjoy being able to see my mouth and my lips when I’m talking. I had a number of patients that are hard of hearing compliment me on being able to look at my face and be able to still read my lips.

From that standpoint, it’s been a tremendous benefit. I see a large volume of patients during the day and being able to wear something that’s comfortable that allows me to see patients throughout the day without having to adjust my mask has been certainly helpful. A lot of the physicians in my practice are using this mask. Even the athletic trainers at our stadium for the Jaguars have been using this mask. The ease of changing the filters makes this also helpful. I can wash my mask down. I can wipe it down. I can take the filters out. They easily pop in and pop out. That’s also helpful. A lot of the cloth masks, if you use them over and over again, you start to get a little bit of fraying of the cloth material. In the throwaway cloth masks, those aren’t protecting you like this type of mask is. From a comfort, protection and patient communication, this mask has checked those boxes for me on a daily basis.

For you on the protocol with the filters, what do you typically observe on filter rotation?

Diana can probably speak to this better than I can, but if you look at how long a virus lasts on a surface, roughly around five days is to my knowledge, where if you’re exposed to a virus, technically if you take those filters out, put them in a bag and you can leave them there and not use them for that period of time, then you can go ahead and switch those out. I’ve bought several filter replacements and swapped those out over a period of a week.

Diana, do you have anything to add?

Diana, do you have anything to add?

That’s the FDA guidance. He’s exactly right. The thing is that you don’t get a lot of wear and tear on that.

For you, Diana, you guys were able to take in and use your existing technology from the casts to go to the masks. What allowed you to be able to add this product line so quickly?

Our expertise was the 3D body imaging, so we can create a 3D body map of any body part and then use our CAD design and our 3D printing to manufacture custom products that are fitted to your exact body map. That can propagate from casts and splints to face masks or any other exoskeleton that you want to use for medical protective products that you might need that’s custom-fitted.

What’s the typical turnaround if you order either the custom scan mask or the one that you’re working on now?

It’s based on demand and the custom fit mask are hand designed, hand manufactured. We 3D print the molds and then we form to them. If we don’t have a huge backlog, it can be anywhere from 1 to 3 weeks. We started out at four weeks because we had thousands of orders coming in, but now it’s reduced down. We’re down to a week. As far as the standard sized ones, those ones we have on inventory. Those ones ship quickly. They’re about a week.

An improperly worn mask is going to allow the air to go in the path of least resistance. Click To TweetDiana, when it comes into that, where are you seeing the predominant type of industries that are using your masks?

We have a lot of service industry people and healthcare. We have a lot of nurses and doctors that are using them, as well as people who are in hotels and customer service and food handling and those kinds of industries because they need that communication. We also have a lot of teachers. We have a lot of first responders, so people like Eric, fire, police, sheriffs’ departments, EMTs, those kinds where they need good communication and they need that custom fit for safety.

Eric, in your experience in working with the Guard, do you think that there’s a demand or that the Guard is going to start looking at these masks across their platform?

I would encourage Diana to look at some grants and some other federal funding because there are some interesting possibilities, especially pilots. I’m on an aircrew in the back of an aircraft where we’ve got microphones that can be custom fit to people’s faces. It’s military. FEMA would be another great market as well. Anybody that’s in the DOD, this is a hot issue.

Circling back to the face fit, Dr. Kaplan, I can remember in the military, we used to put on the chemical gear and the first thing you do is stick it on your face. You’d have to put your hands over the filter ends and suck it in to take and get the seal. Do you think that there’s a recognition of that issue with the standard N95 masks that they don’t have a good seal?

Circling back to the face fit, Dr. Kaplan, I can remember in the military, we used to put on the chemical gear and the first thing you do is stick it on your face. You’d have to put your hands over the filter ends and suck it in to take and get the seal. Do you think that there’s a recognition of that issue with the standard N95 masks that they don’t have a good seal?

I do. An improperly worn mask is going to allow the air to go in the path of least resistance. In seeing patients, I have to wear goggles in addition to a mask. If I were to put on a regular mask, I don’t wear reading glasses, but the goggles, they fog up. You know the air is getting in and out. Hot air is going up. With the ActivArmor mask, I haven’t had that problem at all. Face protection in general is important, but the properly fitted face mask is much safer and can protect you and protect other people from getting this virus that we’re all worried about. It’s much more effective, the better the seal.

For anybody that served in the military that went through a tear gas tent wearing a gas mask, you absolutely know upfront whether you have it sealed properly or not. If you don’t, you get to enjoy the tear gas. You have tangible notice that it’s not working well. The problem that you guys face, if it’s not fitting well, you don’t know. What are you seeing from the professional coaches at the Jaguars? When they’re using the mask, what’s their experience and commentary?

Our head athletic trainer piloted it with the other athletic trainers at the stadium right now. They’ve enjoyed the same type of custom fit. The reason why it’s important for them as well, some of the players that are able to be at the facility are the ones that are rehabilitating from either surgeries that have performance injuries. They’re working close quarters with these players. Protection is a must, and being able to communicate is a must as well. They’ve used this. We were discussing it in terms of our players. Several of our players have trialed this as well, in addition to a lot of the front office. Our coaches are older than our players. They’re concerned about this virus. We’re going to be getting them masks as well. For the coaches trying to communicate to their players, whether it’s in meetings or on the sideline or in practices, communication is paramount. This is going to be a helpful part to our organization as we try to get back on the field.

Do you think you’ll see the linemen and everybody else wearing these masks during practice with the airflow restriction a little challenging?

That could be a challenge. The NFL is trying to work through what they’re going to be doing when we practice. We have a long way to go and the NFL is working through that process now. How often are we going to be tested? How are we going to keep our social distance? How are we going to travel? There are many things at play that I don’t think they have that set in stone in terms of what guys are going to be wearing. Football is a contact sport. They’re very close to each other, especially if you think about getting tackled and having a pile of guys. If one person has it, how close are you going to be? There’s a lot that’s going to go into that decision. I don’t know where we are with what they’re going to wear or if they’re going to wear anything while playing.

That could be a challenge. The NFL is trying to work through what they’re going to be doing when we practice. We have a long way to go and the NFL is working through that process now. How often are we going to be tested? How are we going to keep our social distance? How are we going to travel? There are many things at play that I don’t think they have that set in stone in terms of what guys are going to be wearing. Football is a contact sport. They’re very close to each other, especially if you think about getting tackled and having a pile of guys. If one person has it, how close are you going to be? There’s a lot that’s going to go into that decision. I don’t know where we are with what they’re going to wear or if they’re going to wear anything while playing.

I can imagine trying to call an audible with crowd noise and who knows how well that would transmit, but I can remember trying to run with a gas mask on. That wasn’t much fun just from the airflow restriction. Shifting gears a little bit, Diana, is there anything about the masks that we missed? Maybe talk about on the custom masks versus the non-custom masks or the different price point masks. Talk about the procedure to either get scanned or get their face fitted for one of their sites. What does that process look like?

If you want a custom mask, there are two options. One, if you look at our website, we have some clinics that are scanning clinics like at Jacksonville Orthopedic Institute, and they are providing facial scans to people who want to get custom-fitted facial masks as well and at our providing clinics that also provide ActivArmor. In addition, anyone anywhere can get one of those iPad snap on, which is a structure sensor. It costs around $500 for the whole packet. You snap it onto your iPad or your iPhone and then you do a scan and send it to us and we will make you a custom-fitted mask. As far as the standard sizes, you saw the mask that Eric had. His is a custom one. We have the small narrow, and it fits me. The seal, I had these tested and 5 out of 7 have the fit passed, the standard ones, on 98% of adults. There are templates on our website. If you pick the standard mask, you go there, print out the templates, then try one on. You see which one fits you the best. You can order a standard size mask if you like. Those are much less expensive.

Is there anything that’s been missing from what we’ve talked about? They’re badass looking. When I’m walking through the hospital, people are always staring at me. I wear them in the store or wherever I go. I’m always wearing this thing and I’ve got several of them. I’ve got one in the ICU. One I keep for my flight and I’ve got one in my car. I’ve got a spare. Everywhere you go, everybody stares at you. You hear people as they walk by, “Cool mask,” or “Did you see that mask? Where’d you get that mask?” All the time, you get comments. They’re badass all the way around.

There is that factor. Diana, do you have the one from your daughter at hand?

She painted hers like a stormtrooper. It’s a custom one. It doesn’t fit me because her face is a different shape than mine. You can see how the custom ones are perfectly fitted, whereas the standard ones stick out more on the front. It’s a little bit different. These ones are lower profile and they fit specifically to your face and then standard ones are a little bit different. These ones, I know people like the feel of them around the perimeter and their lower profile. It depends on which one you think you need.

She painted hers like a stormtrooper. It’s a custom one. It doesn’t fit me because her face is a different shape than mine. You can see how the custom ones are perfectly fitted, whereas the standard ones stick out more on the front. It’s a little bit different. These ones are lower profile and they fit specifically to your face and then standard ones are a little bit different. These ones, I know people like the feel of them around the perimeter and their lower profile. It depends on which one you think you need.

Eric, Dr. Kaplan, there are things that I noticed in the pictures that you see of the healthcare workers that have had their mask on for hours and they look like they’ve been beaten. There are marks on their faces and bruises and stuff. For you guys, when you have an extended period of time where you’re wearing the masks, do you have much in the way of that going on?

I don’t have any of that going on. I take the mask off and my face looks like it did before I put the mask on. It’s not these big marks around the face. They’re adjustable. Being that it’s so custom, you need a little bit of a pull, but it’s not like you’re trying to hogtie it when you put it on. My strap below isn’t that tight. The one behind keeps it on and it seals so perfectly. The thing that’s nice about it too is that it’s smooth. It’s plastic. It doesn’t leave marks and doesn’t have an edge to it. It seals across the bridge of your nose and then around your chin. There isn’t a pressure point. There isn’t something that bothers me at the end of the day. I don’t leave with a headache. I don’t leave feeling uncomfortable. That’s a plus. I’m sometimes seeing upwards of 70 patients in a day. Going in and out of rooms and talking and doing all that, if I was wearing an uncomfortable mask all day, it would be extremely irritating.

Prior to this, I had bruises behind my ears and across my nose. It was miserable. I would concur that on a twelve-hour ICU shift, I’ll take it off, maybe pull it down every once in awhile, but if I’ve got it on for hours, nothing like the other mask and the things that you’ve seen on TV with the bruising and things like that.

Diana, the one thing that strikes me and the reason that I asked for you guys to get on the show, I was going, “That’s such a cool product. Why doesn’t everybody know about it?” I don’t understand why the adoption is not wider than it is. What do you think?

It’s about exposure. Nobody knows about it. It’s brand new. I don’t think it’s a problem with demand. It’s a problem with people not knowing about it. These are less than an ounce and they’re like solo cups. They’re super lightweight. That’s another thing. People have those big filter pods and all that stuff, they’re heavy on their face and that super heavy plastic. These ones are nice because they’re super lightweight. That does help a lot. Our company does 3D printing. We don’t even have the distribution model in place to have a new product line in face masks.

ActivArmor™ lets you do things that you couldn't necessarily do in a traditional cast or splint. Click To TweetWe’re not 3M or whatever. It’s about us tapping into that. We’ve used our orthopedic sales reps to get the word out and we’ve used social media and our website, but I would love to have a manufacturing partner who has the market for it, who would take these and run with it. We’re still a little LLC and trying to do custom stuff. The standard masks, they’re like solo cups. You could punch them out by the thousands, mass-manufacture them and do well with it. I’m always looking for any companies or people who want to assist in helping us bring this product to market.

We’re going to shift gears a little bit. We’re going to go away from the product and we’re going to head over to the ActivArmor custom-fitted cast that you’ve made.

While you’re shifting, I got back from a patient. I’ve got a bunch of stuff to do, and this was great. Diana, thank you for asking me. Kevin, it’s great to meet you again. Thank you, Bob. I’m going to check out and get some stuff done.

Eric, thank you for your time. I appreciate it, sincerely.

He transported a COVID patient on a respirator in his helicopter. He had to go and disinfect everything.

He transported a COVID patient on a respirator in his helicopter. He had to go and disinfect everything.

Back to the start part, because we flipped that a little bit because of that eventuality. Talk to me about the cast and for you, it’s been widely covered in other episodes, the genesis of the story and so on. What I thought we would talk about is the journey that an orthopedic practice might go through to look at ActivArmor casts and adoption, the decision process and what that’s like. Diana, what are your thoughts?

The first thing we do is we find our targets and our target is those innovative clinics. At first it was high-end sports medicine, like Dr. Kaplan. He called me. It was funny because I don’t know a lot about sports or athletes. I’m an engineer and I live in my own little nerd bubble. He called me and he said, “I’m the team physician for the Jacksonville Jaguars.” I said, “Great, what is that?” He said, “NFL, football.” I’m like, “How can I help you?” That target at high-end sports medicine was the real starting market entry point for us because people like Dr. Kaplan who are innovative and always trying the latest high-tech solutions for their athletes, because they need to sweat, to shower and to work out in them and be able to do all those things. We thought, “This would be a perfect product for them.” Those kinds of physicians and hospitals get it. It took us five years to get into real mainstream orthopedics. Now we’re in Children’s Hospital Colorado and in a pediatric location, as well as for geriatrics. We’re treating in big hospital networks, making it a standard of care. That was the progression of how we went through, where does this product fit in and how can we bring it to the general mainstream consumer?

Dr. Kaplan, when your orthopedic practice or another one considers using ActivArmor, what are their key decision points to bring that ActivArmor on board?

It started in terms of our use. At least for me personally, I saw a need to have a more anatomically fit cast, one that was hygienic that you could wash and not have to take on and off. Our athletic trainers were having to take casts on and off and make one for practice and one for after practice. It didn’t make sense to me that there wasn’t something out there that was a little bit better fit and custom and something that they could wear all the time and then get wet and get in the shower, etc. That parlayed to our regular practice and the same type of benefits that our athletes are saying or something that our regular patients can use as well.

Where we are in Jacksonville, Florida, it’s about to get 100-plus degrees almost every day. Especially in a younger population, I wore a cast when I was thirteen years old and it was pretty miserable. It was hot, sweaty, and certainly smelly. I couldn’t get in the pool and I had to sit out and it was awful. We haven’t changed much in the way of casting and splinting since I was thirteen years old. That’s striking. To have something like this come along, and there are a number of other problems with traditional casts and splints, from wound issues and diabetic patients where you may not see as some pressure ulcer. These can be serious complications when you have wound problems underneath the cast that you can’t see.

Where we are in Jacksonville, Florida, it’s about to get 100-plus degrees almost every day. Especially in a younger population, I wore a cast when I was thirteen years old and it was pretty miserable. It was hot, sweaty, and certainly smelly. I couldn’t get in the pool and I had to sit out and it was awful. We haven’t changed much in the way of casting and splinting since I was thirteen years old. That’s striking. To have something like this come along, and there are a number of other problems with traditional casts and splints, from wound issues and diabetic patients where you may not see as some pressure ulcer. These can be serious complications when you have wound problems underneath the cast that you can’t see.

There are a lot of reasons why ActivArmor can be a benefit, not only from convenience, comfort, patient satisfaction, being able to do things that you couldn’t necessarily do in a traditional cast or splint. Also, in terms of safety. Being able to monitor the skin if you have an incision, or if you have a wound, being able to see it and a patient is able to see it and say, “There’s a problem with my wound,” or “I’m worried about this,” because we’re looking right at it. There are many reasons why clinics decide when they’re going to go to something like ActivArmor because as you can see, there are a lot of different roads of why this can benefit the patients. If you put them all together, it makes common sense to use it.

When you have a patient that’s first introduced to ActivArmor, what types of questions do you typically get from the patient when you’re first talking about it?

A lot of it has to do with, “How is it different than a regular cast? How will this benefit me?” They’re layup questions because you can simplify. I have a cast of my own that I bring in to the room if I’m going to fit a patient and show them how comfortable it is. I put it up to their arm or I have them try it on and it doesn’t fit their arm. I say, “This is custom made to me. This is printed for my arm specifically.” The patient specificity of these casts and making it anatomic to their own body part is ideal. A cast technician certainly has a skill and an ability to fit a cast, but it’s not to within the 1 millimeter of a patient’s own anatomy. That’s the appeal. This is a custom fit and custom design. You’ll be able to do things like taking a shower without having to put a garbage bag over your arm and avoid the smells and the discomfort of having a regular cast.

You brought back great memories. I had a full cast and I was familiar with garbage bags and duct tape. From a treatment standpoint, with the millimeter difference on the custom cast versus the old plaster cast or fiberglass cast, do you see a better outcome on treating damaged bones and whatnot from that tolerance improvement?

If there is a bone that was fractured and out of place and you’re trying to maintain the alignment, that’s where to within a millimeter would be extremely important. You’re controlling the soft tissues, which are controlling where the bone is in space. That certainly has a benefit. In nondisplaced, meaning the bone may have broken or there is an injury where things haven’t moved apart. I still think to hold the soft tissues in their native position as close to the normal anatomy will allow it to heal much better than if you have a cast that may not be holding as tight to the arm or as specific to the arm and allow the soft tissues to move around a little bit more. I think there’s a role there in terms of patient outcome and satisfaction.

If there is a bone that was fractured and out of place and you’re trying to maintain the alignment, that’s where to within a millimeter would be extremely important. You’re controlling the soft tissues, which are controlling where the bone is in space. That certainly has a benefit. In nondisplaced, meaning the bone may have broken or there is an injury where things haven’t moved apart. I still think to hold the soft tissues in their native position as close to the normal anatomy will allow it to heal much better than if you have a cast that may not be holding as tight to the arm or as specific to the arm and allow the soft tissues to move around a little bit more. I think there’s a role there in terms of patient outcome and satisfaction.

My experience was a soccer break where I kicked a large kid when I wasn’t as large as he was, and I wrapped my leg all the way around his. I had all kinds of floating pieces. It would have been nice to have that opportunity because I got to enjoy getting wedged, which unless you had that done, you don’t appreciate it until they do it.

Wedging and cast is an old school thing that we have to do to try to get the deformity to correct over time. The interesting thing about Diana’s cast and the ActivArmor cast is you still have that ability because soft tissues are going to swell, especially after a fracture. While these things are designed specifically for your anatomy, accounting for swelling is important. Diana has built in a way where you can wedge the cast and allow for swelling and then bring it down and bring it closer together. That’s important. Some surgeons will say, “I don’t want tight-fitting casts,” because you worry about things like the swelling and the pressure and that’s extremely important. If you have a built-in way to relieve some of that pressure while still allowing for the anatomy specific to a patient, that’s a plus.

As you guys looked at this, whether it’s insurance coverage or any other particular pushback, what would you say is the largest pushback that the practice had before adoption?

It’s getting the patients to understand. Diana has been working on this in terms of a billing and coding perspective. The way we’ve done it in our office, the patients have to have a scan that’s where we bill for time from the physical therapist doing the scan and then we bill a regular casting type code. In the same light, there are such things as waterproof casts that we’ve used in the past. Those were similar to the small out of pocket fee. Diana has designed different ways to make this affordable for all the patients. She could probably go into that a little bit on a deeper level, but patients that you present this to who want it are willing to invest in this because it’s specific to them. It’s like investing in anything else that’s made to order or made for you. It’s different than wrapping a cast around the arm.

I grew up in Jacksonville for a number of years. In the summertime, I darn sure want to be able to get in the water. I’m a parent. I don’t want my kids mad at me for however long it takes before they can get in the pool.

3D printing is not plug-and-play still. The technology is not quite there yet. Click To TweetYou know how the weather is. You take a shower, you get outside and it’s like you’re still in the shower. It’s humid and hot. It’s unbelievable. Even at 8:00 at night, it’s still hot. Kids are kids. They run around, do things, get sweaty, get smelly, get dirt and you guys stick in hangers down past the itch. As much of a funny thing it is to stick a hanger down there, that can cause major infections and problems. We’re trying to mitigate the risk of a cast. You can read book chapters on the risks involved with casting. It’s not a simple cast or splint. There are definite risks involved. If we can mitigate some of that risk by using something like this, why not?

Diana, in the COVID pandemic timeframe, what are you seeing as additional commentary about the casts and hygiene and so on?

This being the only cast or splint that you can wash your hands with, the only one that’s sterilizable, it’s huge. Any patient now that has to be immobilized is at risk because they cannot wash whatever it is that’s permanently on covering their hands. That’s a big COVID spreading risk. That’s part of the reason that we want patients to be able to have access to this. All patients, that includes Medicaid, every insurance company, and we are reducing our costs to bring these to patients. Like Dr. Kaplan was saying, part of the problem is that patients have high deductible plans or they don’t have DME coverage at all. Most patients are paying out of pocket for these. We have gotten a cost down now to where they are less than two casts and these ActivArmor casts are reusable.

You don’t have to go in and have a cast cutoff and reapply it and then they transition from a cast to a splint. These ActivArmor devices are cheaper than two casts or splints or whatever you are going to have through your healing phases. This is affordable to everyone now. That’s super important with COVID. You do want it to be available to everyone. These are even cold sterilizable. Doctors like Dr. Kaplan, God forbid he ever gets injured, but if he does, I would hope that you would get a sterilizable cast so that he could end up continuing to do surgery. People in healthcare, in food safety and handling, if they can have this hygienic alternative and it’s the only one that’s available like ActivArmor is, I’m hoping that there’s a big market for it.

Dr. Kaplan, I’m presuming that these have been used with the athletes on the Jaguars. What are you hearing from the athletes as far as their training regimen and outcomes when they’re cast up in ActivArmor?

We initially trialed it on one of our linemen. He had a wrist injury and we wanted to put his wrist in somewhat of a more functional position. The defense, often linemen a lot of times, have their wrists more of an extended position. This wasn’t something we had to completely keep it mobilized, but we made him one cast where his hand was in a normal resting position and then one that put him in his functional football position. He certainly appreciated the ability to do that. We’ve all seen football players play with the full-on club where they have no ability to use their hands because we’re trying to keep something immobilized to protect them from further injury.

With something like this, we were able to put them in a functional position and because it fits well, we allowed him to continue to participate, but also being able to grab is extremely important for a football player. From that standpoint, here’s an athlete who depends on football as his way of making a living. We were able to keep him on the football field simply by using a better cast. Players don’t like it when they don’t have their full function. They don’t feel like they are up to their full potential. Something like this is certainly a benefit in trying to keep these guys on the field.

I think about the pro athlete that’s worked hard to get in the position and there’s always somebody right behind him.

It’s the Wally Pipp story. You lose your spot, you’re Wally Pipped.

I can see from the athlete that’s injured who goes, “Yes, this is an alternative to perhaps still staying in the game and still playing and being functional.”

Diana was at our NFL Combine with ActivArmor and introducing this to a lot of other teams, which much to my dismay, I like having something that’s special for the Jaguars as much of an advantage as possible. I’m kidding. We’re collegial NFL. A lot of the other athletic trainers and team positions are starting to look at this and see it as a benefit. The athletic trainers, there’s no question. They’re dealing with 54 players on a day in and day out basis. If you have 3 or 4 players that need a cast, that’s a lot of manpower and time taking on a cast, putting on a cast, making another cast. If you can simply have your game cast and you’re walking around a cast that is custom fit, that saves a lot of time and allows them to work with other players. It’s a benefit to the player and a benefit to the working staff. It’s a win-win.

Diana, you’re not injured. You have your custom cast. Can you show how that goes on and off?

This one is removable. I wear this one for a carpal tunnel. I always joke around that I got carpal tunnel from making carpal tunnel devices, but it’s true that if you want to have it be lightweight and removable for a chronic condition like carpal tunnel, you can have these little bunches that allow you to remove it and pop it off and on super easy. It easily stretches on and off. If you want it locked on like a cast, you can have them locked. These bunches aren’t there. You have enclosed zip ties that go in there. You have to have a little clipper and you clip them off and that locks it on. For pediatric patients or anyone who you’re worried about compliance, you can make it as thick or as thin as you want. That way it will be more protective like a cast or you can have one that’s even a little flexible.

One of the coatings that we have in this is called PAXCON coating. It’s made by LINE-X. It’s biocompatible, so you can wear it on your skin. They use it like Kevlar for body armor. It’s crazy strong. I’ve had this for years and that’s what we put on the Jaguars. We coat that from a thicker device or any of the NFL players that want that impact resistance. We will coat it with this crazy strong coating, which makes it indestructible. It always scares me because those guys go out there on the field with your traditional cast. If they fall down the stairs or whatever, you’re going to break your fingers, or you’re going to break your arm above or below the cast because this is going to protect you.

I had one patient that was playing hockey and a puck hit his cast and he didn’t have the coating on it. It was a plastic cast and it got a little crack in it, but it saved his arm. I was like, “I couldn’t even imagine what that would have done to your bone if it wouldn’t have protected it. That’s the cool thing that Dr. Kaplan gets the customization ability where he can say, “This patient has pins or incision that needs to be exposed or offset,” or “This patient has a bony protrusion that they need to accommodate,” or “This patient wants a bone stimulator, a muscle stimulator, a TENS unit for pain management.”

We custom design it for each patient. It helps them with their lifestyle, as well as the doctors being able to observe and treat the skin. That one 49er player, Trent Taylor I believe, that had the leg cast. They didn’t know until they cut his cast off that he had an infection from his surgical incision underneath it. He was out for the whole season. There are other patients where you can’t see if there’s swelling coming up underneath the cast until it comes up to your hand, there’s a high risk for compartment syndrome, which is dangerous for patients. If you can’t see an infection until it’s all the way on the outside of the cast, that’s a problem.

It’s the same thing with the mask and the cast. The whole point of it is visibility. You can see what’s going on underneath the device and be able to treat it and treat the patient while they’re being immobilized, which is hugely beneficial as far as catching infections. Some of the reports that we’ve gotten from other physicians and practices that have been that, it reduces your infection risk as well as any negative healing outcomes that they have because you can observe. You see there’s movement underneath the cast and they need to tighten it up because swelling went down or they got muscle atrophy and the patient’s not immobilized. You can see that and immediately make those adjustments to improve your outcomes for that patient. Also, if there’s an incision starting to get infected, you can treat it. You can put any medications on or anything and observe it. That’s a nice benefit of ActivArmor versus a traditional one.

For that cast, I have no idea the weight of that. What would the weight be of that cast?

This one is 3 ounces. If you get a full arm cast or whatever, on average, our cast is half the weight of a traditional fiberglass cast. They’re super lightweight, but they can be anything that you want as protective as a traditional cast.

We talked about that beforehand, that the LINE-X for the folks that rings a bell, that’s the liner of your pickup truck bed. At least that’s the LINE-X that I know. That’s the company. You’ve got the coating inside there, which adds a real durability dimension to the product.

It’s ISO-certified for biocompatibility. You can wear it against your skin. You’re not wearing a truck bed, but I want to make sure that everybody understands that this is safe and this is a medical device. Also, the military is using it as body armor. It’s nice because the custom-fitted body armor is low profile too. It allows them to be able to perform all of their active functions that they need to do in the field while they’re immobilized or while they’re protected.

The motivation behind this, I was impressed and enamored when I saw it. You’re down the street from me in Colorado Springs, and Dr. Kaplan is down where they have a beach instead of just sand, which we have lots of sand. In looking at that, I wanted to get the word out about the product. I thought it was clever. Having some level of experience with the cast for months, I’m envious they didn’t have it when I had my problem. When you look at that, one of the things that we talked about, Diana, in the past is your ability to do custom design mask production. I thought that was a rather interesting thought process. I don’t know if you want to touch on that or not.

I did a little bit of a TEDx Talk about local mask customization. I’m sure Dr. Kaplan can talk about this more, but I grew up in a children’s hospital when my brother had cystic fibrosis. I would always see patients having to adapt to medical devices as opposed to the other way around. There is no one size fits all. As Dr. Kaplan can attest, when you get braces that are off the shelf and they come in extra small through extra large and you have to fit them to the patient how many times because it does not fit a patient or it doesn’t work for a patient. You can see the shape of my arm compared to the shape of an NFL player’s are completely different and our needs are completely different.

There’s one company that’s trying to sell 3D printers to doctors and hospitals and it’s not successful. Part of the reason for that is that 3D printing is not plug and play still. The technology is not quite there yet. There are a lot of factors that you have to address. Hot plastics and solvents, calibration of equipment, CAD design experience, expertise and all of those things. They make it hard for doctors, hospitals and clinics to innovate and do new things like that. It’s not like, “I’ll give you a machine and you put it in here, you press start and out comes a custom cast.” It doesn’t work like that. With all the regulatory requirements with the FDA for medical devices and that medical device manufacturer and everything, it’s hard for clinics to provide you products and not have it be cumbersome.

They’re already strapped, as I’m sure Dr. Kaplan can tell you. Your staff is strapped all the time. You guys are booked with patients. The whole goal is for you to be able to see and treat and help as many people as you possibly can in time. You guys don’t want to be messing around with medical device manufacturing and testing and all of that. We try to do a mask production type of a deal on custom devices when every single one is unique. That’s why 3D printing is great. You can make products on-demand and custom-designed, but it is hard to mass-produce like that because all of your efficiencies of scale, for example, like the masks, the custom ones are more expensive than the standard ones because these are like solo cups.

You could have plastic and punch a whole bunch of them out and have inventory and then fill the need. When you get to custom fitting things, every single one has to be hand manufactured, hand finished and quality control checked and shipped specifically for that patient. There are a lot of logistics and a lot of labor. It’s a lot more labor-intensive for custom devices than there is for off the shelf standard devices. That’s why a lot of people aren’t doing it. It’s expensive to do custom design, manufacturing and finishing. That’s why a lot of people don’t go down that path to standardize things. We want to make it custom because people need that.

Dr. Kaplan, you’ve had an extremely long day, I suspect. I can’t tell you how much I appreciate you taking time out of your day to come and visit with us and talk about ActivArmor. I believe in what they do and the contribution that they’re making. I honor and appreciate all the time, effort and money you spent to get to where you are. I’m a former pre-med kid, then Organic Chemistry decided to get in the way. That’s the story of many. For people that want to reach out to you, how do they find you and the Jacksonville Orthopedic Institute? How do they find you guys?

I’m honored to be here. I think Diana has come up with something that’s completely innovative and has changed part of our orthopedic world that has been largely unchanged for many years. I’m proud to support her and the efforts that she’s made. We’re a big group down here in Jacksonville expanding not only locally, but nationally. I have my own website. That’s my name, KevinKaplanMD.com. Our group is JOI.net. We’re seeing patients from all over. Some of those patients have come looking for ActivArmor. Patients from Atlanta come see us and come in from down South. We’re constantly expanding and looking to become even more of a nationally recognized area in terms of our medical care. Through innovative things like this, we’re doing that. I’m happy to see patients. I get patients that I’ve operated on from Vegas, California and New York. We’re proud to do that. I appreciate you giving me the opportunity to be on with you.

Thank you so much. We appreciate your perspectives and insights. For the people that are out reading, it’s important to consider all the options and it’s gone through the regulatory process. It’s tested in the field and in the athletic arena. There’s sufficient evidence behind all of this too. If you have this type of event happen in your life, you’d be remiss not to take it in or rule it out. Diana, you and I have been attempting to connect for some time and I appreciate you, the busy entrepreneur, trying to get all of this done and run the company and so on. In thinking about it, if you were to reach out to people that are either interested in using the product understanding more or perhaps participating in the growth of ActivArmor, what might you say to that cohort of folks?

I would say hit us on at ActivArmor.com. Follow us on Facebook, Twitter, Instagram, LinkedIn. It’s the same. Look for ActivArmor. We are always looking for partners in manufacturing the masks, in the distribution for those. For investors who want to come on board, I still have an LLC. We’re still in our seed funding round. If you’re interested in getting on and becoming a partner, you can do that. You can also become a sales rep. We’re looking for distributors. We’re looking for partnering in clinics and physician providers who want to have their logo on every single device and do like a Jacksonville Orthopedic Institute where they have people coming in from all over the country to find your clinic. We only have fourteen clinics across the country now. We’re always happy to open up. I was talking to the clinic in Hawaii, so I’m excited about opening up there. I want to go there.

You’re going to have to have a different color than black though.

You can have them flashy. They like the yellow there, whatever you want, but surfers love them. We’re looking also for partners and help at any time. Reach out to us. On our website, if you go to Info, I can get it. You can call me on that 1-800 number. You can get me directly or you can get one of my staff. We would love to have any help from anybody and bring it to your town.

It’s been a privilege to have you guys on the episode. I appreciate your time and insights, Dr. Kaplan. Thanks for all that you do. Diana, I appreciate you being a guest on the show.

Thank you. I appreciate it.

Thanks, guys.

Important Links:

- Dr. Kevin Kaplan

- Eric Miller – LinkedIn

- TEDx Talk – Diana Hall

- JOI.net

- Facebook – ActivArmor

- Twitter – ActivArmor

- Instagram – ActivArmor

- LinkedIn – ActivArmor

- ActivArmor.com

Love the show? Subscribe, rate, review, and share!

Join the Business Leaders Podcast Community today: